V-Dock’s History

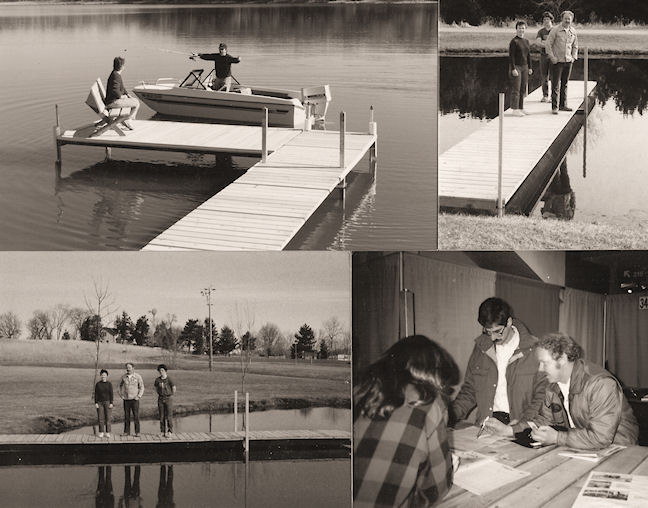

It all Started…….

In the early 80’s, Dick Johnson decided to start his own business and purchased 6 acres of land in Forest Lake, Minnesota. With the help of friends and family, he erected a pole building on the corner of the land. He named the business “R & D Manufacturing”, anticipating that some day his 12 year old son, “R”ick, would join “D”ick in the family business. Now he had to decide what kind of business it would be?

Dick Johnson was a problem solver, inventor, designer, “idea man”, yet he didn’t know what direction to focus his talents. Growing up, Dick worked at his father’s gas station in Big Fork, MN. Dick trained to be a welder at a local vocational school. In 1967, he was drafted into the Army and sent to Germany. They soon discovered his talents as a welder and moved Dick out of the infantry division to the headquarters maintenance shop. When he got out of the Army, he was hired to do welding by a large specialty manufacturer. He was quickly promoted to “Manufacturing Engineer”. Over the years, he learned how to do many different jobs: machining, welding, auto repair, metal work, tool and die making, and metal fabrication, just to name a few. He was a “jack of all trades” and didn’t know what to master in.

Dick and his family lived in the “Land of 10,000 Lakes”, where the American dream was not just to own a little white house with a picket fence, but to someday own a cabin on a lake. That got Dick thinking that all those cabins were going to need a dock. Dick noticed that all docks looked and performed pretty much the same. And people had many complaints about their docks; complaints he set out to solve.

Complaint #1: Unstable Docks…. While the docks on the market would support the weight of people, they would bounce and sway when walked on making them feel unsafe. All the docks on the market used a truss-like frame system to support the walkway.

Solution: ..a “V” shaped beam. Using a roll-formed “V”-beam offered better support than the standard truss-system. The “V”-beam has four continuous points of support across the decking as opposed to only two. The “V” shape also gave the dock the flexibility to absorb the impact of someone walking on the dock, reducing sway and bounce. Some added benefits of this continuous “V”-beam were that it gave the dock a clean, sleek look; there was no place for unsightly weeds to get hung up under the dock; there was no open truss for kids to get their foot caught in, increasing safety; and there was no metal near the edges to scratch up boats. On the rolling sundecks, we improved stability by putting a set of wheels on the front and the back, instead of in the middle, like a teeter-totter.

Complaint #2: Takes all weekend and 5 neighbors to install a dock… It seemed to Dick that there had to be a simpler way to attach the posts than using a sleeve. Installation required someone to lift the entire frame up and drop the sleeve down onto a post. If the post was bent or out-of-round, that made installation even more difficult.

Solution: ..a “U” shaped bracket. V-Dock’s exclusive post bracket design makes the installation of posts a snap.

Complaint #3: Need to take the dock out in sections…

Solution: ..use a connecting pin between each section that allows each joint to flex, like a hinge, yet remain connected as the dock rolls out up a hill or over rip rap.

Complaint #4: Adjusting the dock height when water levels changed, was a like reinstalling the dock. Using a winch was an improvement, but it was still cumbersome.

Solution: ..a built-in screw drive leg mechanism. R & D Manufacturing was one of the first dock companies to use a telescoping leg. Now the level of the dock could be adjusted simply by turning a bolt on the top of each leg.

Complaint #5: Too Much Maintenance…Life at the cabin was supposed to be relaxing, but staining and sealing the dock every year or replacing boards was a chore.

Solution: ..maintenance-free Poly-Deck. Other companies had gone to aluminum decking, which was lightweight, yet noisy, rough, and hard to make slip resistant. Plastic decking was beginning to emerge, but no one had perfected it. R & D Manufacturing set out to make their own decking. Drawing from years of experience in manufacturing, Dick designed a molded polypropylene deck board, specifically for the “V”-beam framework, that was lightweight, durable, skid-resistant, and maintenance-free. Consequently, a V-dock can be installed with the decking in place saving the owner time and backaches. Some addition benefits of V-Dock’s molded decking is that the rounded edges look nicer, are gentler on users and boats, and it adds strength to the edges where people would be stepping off the dock into boats or jumping into the lake.

Complaint #6: Pneumatic tires on the roll-in docks would go flat.

Solution: ..make custom tires out of plastic. Other dock companies were buying a general purpose plastic balloon tire; not specifically designed for use on a dock. After years of experience with different size pneumatic tires, Dick knew that the optimal tire size was 26″ in diameter and about 6″ in width. The basic principals behind the wagon wheel and the tall skinny tires on Ford’s Model “A” that allowed them to travel easily on dirt roads, applied to dock tires. The larger the diameter, the easier it is to roll. A thin tire, like on a bicycle, would sink down in the muck, but if there was too much surface area it creates drag.

Complaint #7: Docks were Heavy. Like everyone else, Dick had built his original docks with galvanized steel frames and wooden decking. This made the docks very heavy to install.

Solution: ..switch to aluminum “V” beams. With the proper thickness of aluminum, V-Dock’s “V”-beam could still support ample load, yet the total weight of the dock was cut by 66%. This decision also increased the flexibility of the dock, further eliminating sway and bounce. Changing to poly-decking also reduced the total weight of the dock and allowed the customer to install the dock with the decking on!

Although there have been many improvements over the years, the simplicity and genius of V-Dock’s original design has held true. Customers who purchased our very first docks can still add on a new section.

…at is unheard of in most businesses today

Pride in Ownership

After 32 years, R & D Manufacturing is still a family-run business. Everything is made right here in Forest Lake on the original property Dick purchased in 1981. We work hard every day to produce a high quality product, to ensure our customers’ satisfaction. We believe their happiness is key to our family’s future.

The company philosophy is: “Build a great product and it will sell itself”. There is no need for high pressure sales techniques or commissioned sales people. What we do have is hundreds of loyal customers who love to tell their friends, neighbors and relatives all the benefits of owning a V-Dock. More than half of our new customers know someone who owns a V-Dock. So we would like to take this opportunity to say

“Thanks” to all our customers for their excellent referrals that have kept us going strong over the years.

Family Owned

Dick & Marilyn

Marissa, Rick, Stephaine, Amy, and Brandon